Caulking and injection sealing

⒈ Application scope and operation method

When there is leak at the flange sealing surface, we usually apply clamp injection method. We need to design and manufacture clamp before the operation. If the upper and lower flange is not concentric or has irregular shape, it would be difficult to manufacture the clamp. The following is the introduction of the simple way for the sealing method.

⑴ Application scope

① suitable for the gaskets of different shape like round, oval, square, etc.

② suitable for system temperature

③ leaking flange connecting gap≤

⑵ Operation method

① Pack the proper specification of metallic wire into the flange connecting gap. Caulk the flange edge to form the sealing cavity and inject the sealant.

② If the diameter of the leaking flange is large and is partial leak, it could apply partial sealing method.

③ If the system pressure is less than 2MPa, it could apply the screw filling joint and inject the sealant through the threaded channel between flange bolt and bolt hole.

1-screw filling joint;

2-injection channel;

3-sealing cavity;

4-brass wire

④ If the system pressure is more than 2MPa,it should drill the hole at the flange edge and tap it, and connect the injection valve.

⑤ If it applies partial sealing method, it should be reinforced at two ends to avoid the sealant coming out from the sealing cavity.

2, Operation procedure

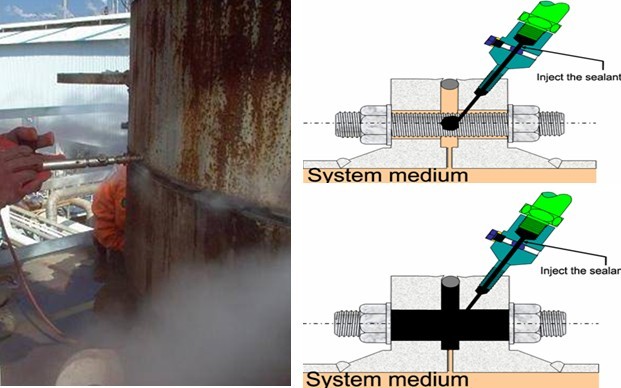

⑴.At the proper location of the flange edge and flange surface, dill the hole and tape in slant direction, and then connect the injection valve:

⑵.Apply φ4 drill bit to drill through the remaining thickness of the wall, and let the injection valve face straightly toward the flange connecting gap.

Drill through the remaining thickness of the wall and lead the medium out

⑶. Pack the metallic wire of proper specification in the flange connection gap

⑷. Use air hammer to caulk the flange outer edge to block the metallic wire.

⑸. Close the valve of the initial injection port and connect the injection gun.

3 Sealant selection

⑴ Sealant property

① The injection property of Txy-8#

a. It has no curing process, excellent injection flowability, stable chemical property, and suitable for wide range of leaking medium.

b. Strong cold flow property, and good mouldability under the temperature of

② The property characteristics of Txy-18#、Txy-16#

a. The performance of Txy-18#、Txy-16#

b. Performance characteristics

Txy-18# sealant is suitable for wide range of leaking medium, and its formulation content contains blocking material, which can soon form the pressure-bearing capability.

It applies vulcanizing system in sealant Txy-16# and excellent plastic fluidity.

⑵ The suitability of Txy-8#、Txy-16#、Txy-18#

①Applicable temperature of Txy-8#:

②The applicable temperature of Txy-16#:

③Txy-18# is used under temperature

⑶ Sealant selecting principle

Select based on system temperature, leaking medium, and leaking condition.

4,Partial sealing operation method

If the flange outer diameter is more thanφ600, it could seal for partial sealing method.

⑴ Relevant specification of the pressure parts for partial sealing

① The specification for metallic wire

a, The diameter of the metallic wire should be slightly larger than that of flange connection gap;

b, The metallic wire should have the length which would extend for 1~2 flange bolt from the leaking location;

c, Forge the contact section of two metallic wire ends for close touch to the end plates.

② End plate shape and its relevant specification

a, See end plates image

b, Relevant specification

thickness:F= flange connection gap

length:A= the distance between flange edge and sealing washer-0.95× edge length of radial direction of brass wire cross section;

Gap diameter:φ= flange screw diameter+

Gap center position:

E = (D-K)/2-edge length of radial direction of brass wire cross section;

K – the diameter of flange bolt hole;

the width of the end plate:B=φ+2×(15~20)

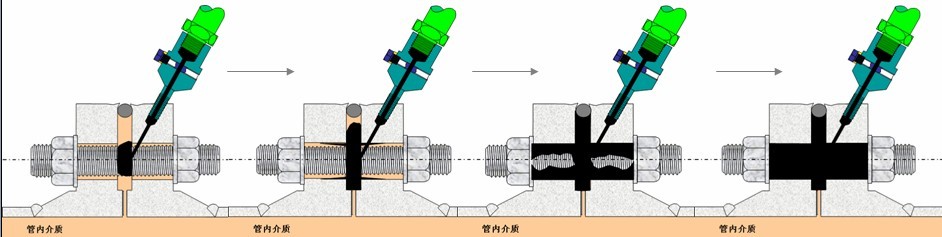

⑵ Injection procedure

① Inject from the two ports which is at two ends of the cover and pause for a while for sealant curing there as a block at the border;

② Inject symmetrically toward the center port;

③ Control the injection speed to coordinate with the sealant curing time to avoid the sealant coming out from sealing cavity or leaking into the running system;

④ Under the low system temperature or applying the filling type sealant, it should press slowly and steadily;

⑤ Make complementary injection and compact to avoid of stress relaxation.

⑶ The Sealant dynamic change in the filling process

5, Technique characteristics

⑴ suitable for different type of sealing washer surface, and not affected by the slight mismatching and eccentric center or of upper and lower flange;

⑵ easy operation; no need for clamp design and manufacture;

⑶ shorten the sealant flowing distance, and suitable for control of the injection speed and sealant curing time;

⑷ good for enhance the filling quality.

|

China Contact

Tel: +86-22-23111200 Fax: +86-22-23301140 |

TXY-TECH INC, 9894 Bissonet, Suite 987, Houston, TX 77036

Tel: (510) 220-5689 (510) 502-1227 |